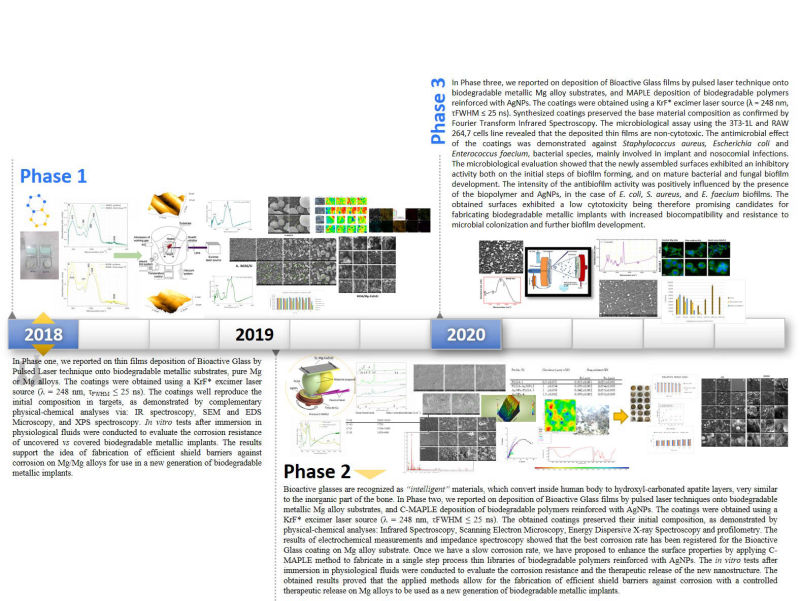

Project Phases 2018-2020

Project Phases 2018-2020

Overall Project Conclusions

Overall Project Conclusions

Project number PD52/2018

This contract is financed by

Romanian National Authority for Scientific Research,

CNCS-UEFISCDI

Project code : PN-III-P1-1.1-PD-2016-1219

Nowadays, the progress in surgical techniques has led to an explosive growth in the use of biomaterials for advanced medical devices and smart implants.

The concept of a biodegradable metallic implant (BMI) able to help bony tissues to regenerate, stimulated numerous research teams around the world to test new biomaterials and combinations of biomaterials aiming towards, biomimetism. The idea is that new kinds of BMIs based on pure Magnesium (Mg) or alloys can adapt to the body and eventually dissolve after the surgery regions have healed. The main issue of using Mg/Mg alloys as BMIs is their rapidly corrosion rates in physiological environments. Moreover, another problem related to the corrosion process is the production of Hydrogen gas which can be accumulated in the interstices next to the implant or can form subcutaneous bubbles. Consequently, they degrade faster than the time required for bone healing. There are many research studies reported in the literature on Mg/Mg alloys based on different combinations of biomaterials in order to fulfill all the requirements for fabrication of an ideal BMI. However, many studies are not supported by enough data and evidences from the real degradation behavior in vivo or from the point of view of adverse effects which can take place in the healing process of the bone.

Bioactive materials play an increasingly important role in the biomaterials industry, and are used extensively in a range of applications, including MIs. Bioactive materials are capable to form a hydroxyl-carbonated apatite layer on the surface. The crystallization of the Calcium Phosphate (CaP) occurs by incorporating OH− and CO3− from the solution and form a bioapatite layer. Belonging to this category are the Bioactive Glasses (BG). BGs are “intelligent materials”, superior in bioactivity to CaPs. They are based on various metal oxide combinations of SiO2, Na2O, CaO and P2O5 in specific proportions. We try to develop new solutions for surface modification in terms of controlling the corrosion rate of Mg/Mg alloys MIs in form of novel BG thin coatings. On the other hand, on the surface of MIs bacterial and fungal biofilms can be developed after surgical operation of implantation. To counteract this major risk, we propose with this project to cover the implant not only with BG but also with antimicrobial agents.

Today, it is widely accepted that laser-based technologies are among the main, most powerful tools for the fabrication of micro- and nano-arrays of wide-range of different biomaterials with controlled thickness (with the precision of 1 Å), good adhesion to the substrate and specific surface properties. Pulsed laser deposition- PLD technique proved to be a competitive method to grow high-quality biomaterial coatings as it is preserving the complex stoichiometry of deposited compounds.

On this basis, we will develop solutions for surface modification in terms of structural and functional properties by using novel metamaterial made from assemblies of multiple elements obtained from composite materials. Concretely, we propose the development of new biodegradable structures which will accomplish all the criteria for the development of a next-generation of implants with superior performances.

Project Leader : Dr. Natalia Mihailescu

Coordinator : Prof. Dr. Ing Anton Ficai

1. University “Politehnică” Bucharest , Faculty of Applied Chemistry and Material Science - ROMANIA

2. Center for Advanced Laser Technologies (CETAL), Biological Testing Laboratory - ROMANIA

3. University “Transilvania” Brașov - ROMANIA

4. University of Bucharest, Faculty of Biology - ROMANIA;

1. It will be developed new and improved BMIs with tailored properties or functionalities induced by a new metamaterial surface, using complementary pulsed laser techniques, which will provide long-term corrosion protection and good osseointegration.

2. New products for orthopedic surgery in the form of BMIs modified with thin coatings to support the mechanical integrity, protection against biofilm associated infections, and an early osseointegration processes by increasing cell proliferation.

3. Promotion of clean, efficient and environmental friendly synthesis techniques.

Conferences

1. International Symposium of Chemical Engineering and Materials, SICHEM 2018, University Politehnica of Bucharest, Romania, 6-7 September; Poster presentation “A comparative study of pure Mg/Mg–based alloys for metallic implants application”, Natalia Mihailescu, I. Ungureanu (Negut), A. Ficai, Roxana Truscă, Dragos Gudovan, Laura Floroian, and Ion N. Mihailescu.

2. The 12th European Symposium on Thermal Analysis and Calorimetry (ESTAC12) 27 and 30 August 2018 in Brasov, Romania. Poster presentation “Nanostructured bioactive glass coatings synthesized by pulsed laser deposition onto biodegradable metallic implants”, Natalia Mihailescu, M. Sopronyi, A. Ficai, Laura Floroian, Irina Negut, Carmen Ristoscu, G. Stan, José M.F. Ferreira and Ion N. Mihailescu.

Articles

1. “Gradient multifunctional biopolymer thin film assemblies synthesized by Combinatorial MAPLE”, Natalia Mihailescu, Merve Erginer Haskoylu, Carmen Ristoscu, Müge Sennaroglu Bostan, Mihai Sopronyi, Mehmet S. Eroğlu, Mariana Carmen Chifiriuc, Cosmin Catalin Mustaciosu, Emanuel Axente, Ebru Toksoy Oner, Ion N. Mihailescud, Applied Surface Science, Pub Date : 2018-10-09 DOI: 10.1016/j.apsusc.2018.10.077, Volume 466, 1 February 2019, Pages 628-636.

2. Alexa-Maria Croitoru, Denisa Ficai, Anton Ficai, Natalia Mihailescu*, Ecaterina Andronescu and Claudiu Florin Turculet „Nanostructured fibers containing natural or synthetic bioactive compounds in wound dressing applications”, trimis spre publicare la Jurnalul Matreials, 2020