This contract focuses on the synthesis by pulsed laser deposition of hard carbon films and their physico-chemical, mechanical and tribological characterization. Diverse amorphous or nanocrystaline structures with different sp3/sp2 ratio will be obtained, by varying deposition parameters such as fluence, atmosphere, pressure, substrate temperature, target-substrate separation distance. All deposited films will be preliminary characterized in terms hardness. The most interesting structures will be investigated by SEM, AFM, XRD, XRR, XPS or Raman spectroscopy and mechanically in terms of adherence, hardness, Young modulus, wear resistance and fretting. The evolution of mechanical properties function of films structure will be observed by tracing diagrams “deposition parameter/carbon structure” and “hardness/structural parameter”. A model that takes into account structural parameters of carbon films to explain the evolution of mechanical properties will be developed. Metallurgical cutting blades and piercing drills will be covered by PLD with the best carbon films in terms of mechanical properties and studied in real applications susceptible to wear and high temperatures. The coatings will be subsequently studied for wear signs, cracks and delamination. A microscopic comparison with uncoated or WC and ZrC carbide coated standard tools will be performed. The final goal is to obtain tools covered with carbon films by PLD superior in resistance to commercially available solutions.

Fig.1 Cross-section visualization by SEM of a carbon thin film

synthesized by pulsed laser deposition

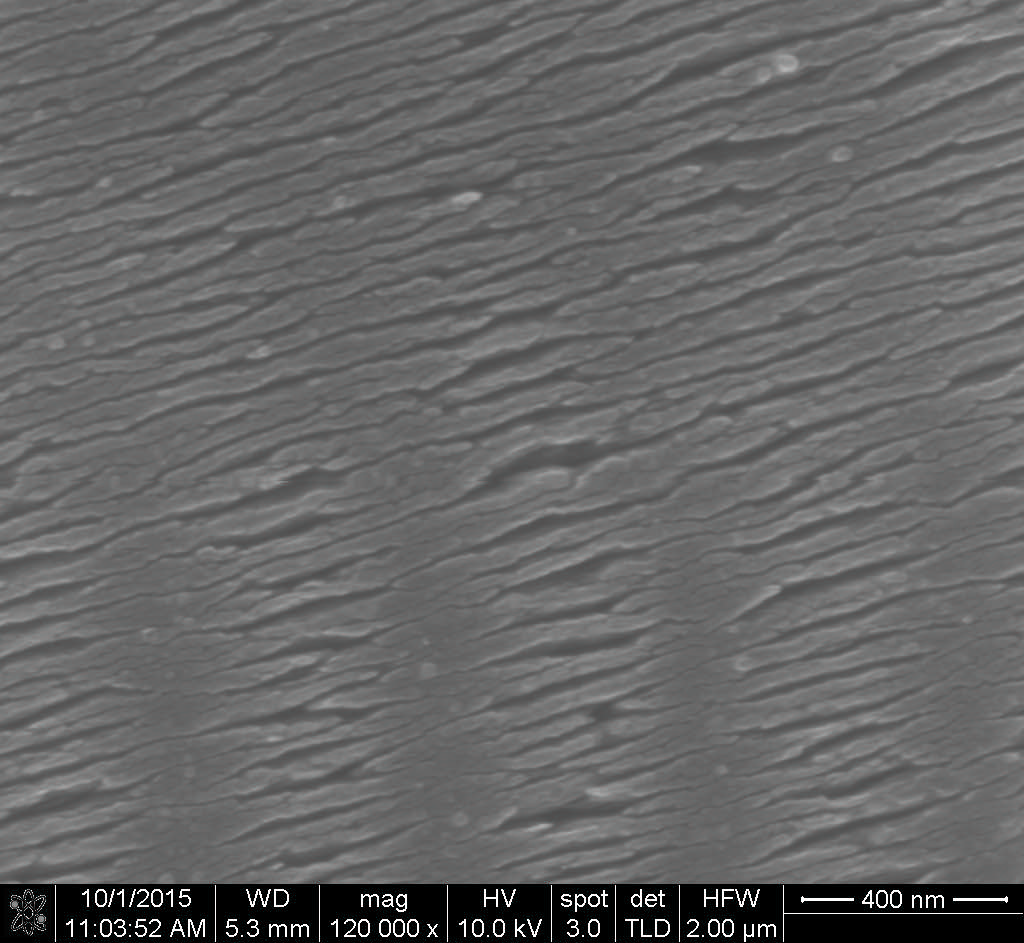

Fig.2 Nanostructuring of

the film by

laser irradiation for reducition of the friction coefficient