The large-scale development of implants in different medical fields is unfortunately restricted by a growing number of related infections. The associated severe complications oftenly lead to prolonged patient excruciating pains, increased costs and possible implant loss and mandatory revision. Nosocomial infections result from the reaction via an infectious agent or toxin and constitute a major problem with high incidence, morbidity and mortality rates worldwide in health institutions. Enhanced prevention and control of nosocomial infections is therefore a current strategic priority for hospitals and other health institutions worldwide. One major strategy proceeds by the design of antimicrobial coatings based on antibiotics which preserve for a long time a good efficiency and appropriate mechanical properties.

The major barrier to be surpassed in this case is related to antibiotic resistance, which occurs whenever the microbes change in a way to either reduce or eliminate the effectiveness of drugs, chemicals, or other agents patterned to cure or prevent infections. Microbes survive and continue to multiply causing more harm. The resistance to microbial adherence, colonization and biofilms development could be achieved by over-coating with a thin layer containing natural that keep active in long time. The quasi majority of exiting coatings methods (e.g., cold spraying, dip coating, electrochemical methods, electrophoretic deposition, magnetron sputtering, photochemical oxidation, and Matrix-Assisted Pulsed Laser Evaporation (MAPLE) is resort to drugs, mainly antibiotics. The antimicrobial action of these substances rapidly decreases in time and continuously supply is mandatory.

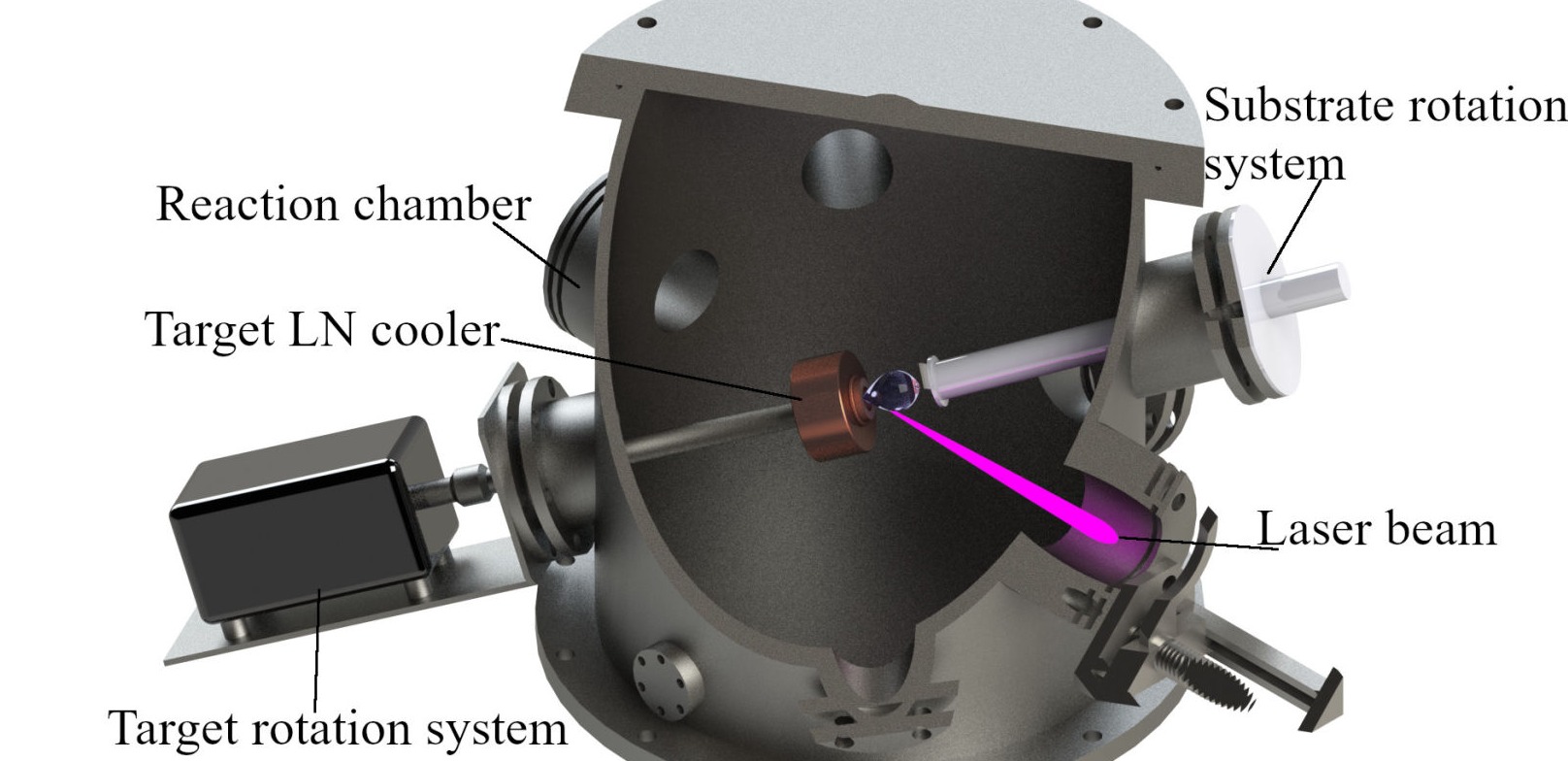

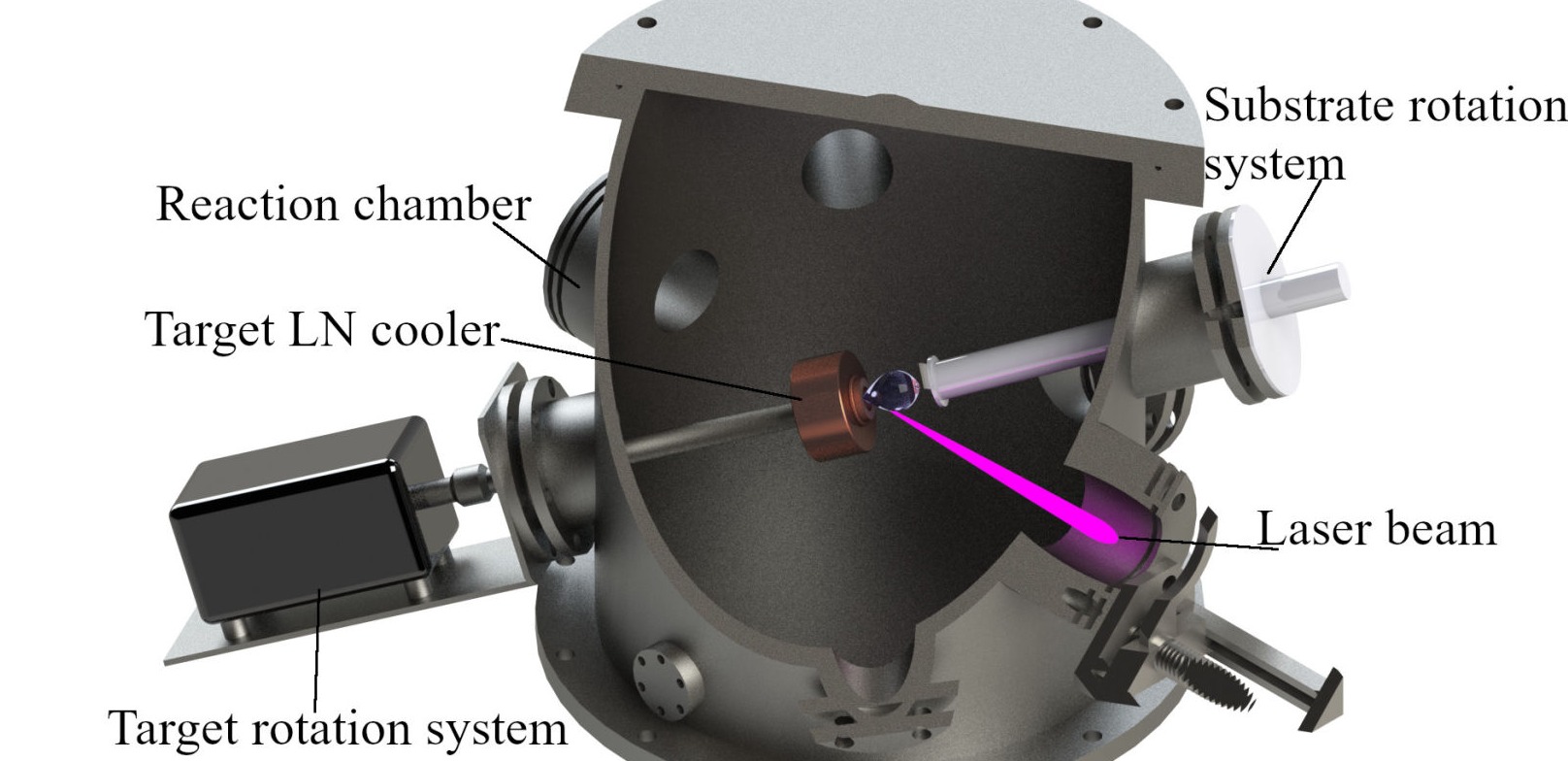

A basically new approach is proposed with this project by MAPLE extension to fabricate antimicrobial coatings for prevention/eradication of inherent surface infections followed by local, sustained of antimicrobial natural agents delivery.